Automatic Program Selection

| ||

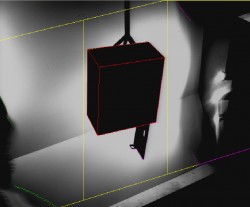

The hotel deposit safes are transported on a hanging conveyor. The vision system takes an image of the safe in motion, then it identifies the type and transmits the id to the paint robot. The robot selects the paint program according to the id. Different products may arrive in a random sequence. The system is at the same time keeping track of the product queues in to and out from the robot.

The vision system is a tool and are configured by the operator. The normal procedure is to take a picture of each safe and then give the reference image a name and an id-code. The system creates a number of attributes, based on the images, to describe each product type. This is used for automatic identification. System verification is performed by manually entering the products into the input queue and then comparing the queue with the automatic identification.

Arne Ivar Sundseth, Production Manager of Elsafe International AS, comments: "TORDIVEL AS was recommended to us by ABB and since our first meeting in January we have felt that we are safe in the hands of a professional supplier. The system was installed at the end of March and after a week's commissioning, we could identify hotel safes on a continuous basis and can insert new safes ourselves as new models come into production. With the system's built-in functions for remote control we can rest assured that it will be monitored so that any operational problems can be quickly corrected. Our conclusion is that we are very pleased with our first VISION SYSTEM."